What you'll learn:

- What is the IEEE 10BASE-T1L physical-layer standard?

- How does the standard enable new health asset insights?

- SPoE combined with 10BASE-T1L PHY efficiently delivers power and data over a single twisted-pair cable.

随着制造商和工厂运营商希望增加吞吐量,同时降低维护成本和资产的停机时间,实时,连续,状况监测和预测维护解决方案的重要性不断增长。条件监测可以延长设备寿命,提高制造质量并提高制造厂的安全性。

Specifically,基于条件的监控结合人工智能可以用来部署端到端监视和预测维护服务。鉴于未定的停机时间可以达到制造总成本的近四分之一,因此预测维护有可能释放大量的节省和生产率。1

Industry market reports focused on condition monitoring and predictive maintenance project compound annual growth rates (CAGR) of 25% to 40%, as driven by two growth areas. The first is the increased deployment of smart sensors to monitor asset health. The second growth area is the escalating use of artificial intelligence and advanced analytics to transform asset health data into actionable insights for predictive maintenance and create new service-based, predictive-maintenance business model opportunities. The ramp-up in new condition-monitoring deployments will range across multiple industries, including:

- 废物和废水处理

- 制造业

- 纸和纸浆

- 食品与饮品

- 药物

- Metal and mining

- 活力

- 油气装置

Within these industries, condition monitoring applications are expanding beyond the traditional rotating equipment applications (pumps, compressors, and fans) to new applications in CNC machines, machine tools, encoders, conveyor belts, robotics, and instruments(图。1)。

现有的沟通挑战

从智能传感器到高级管理系统的连接性一直是条件监控应用程序的关键挑战之一。迄今为止,此类应用程序根据最终申请要求使用了有线或无线连接解决方案。

无线连接性解决方案在易于部署方面具有优势,但在带宽和/或电池寿命方面通常受到限制。有线连接性解决方案有时在数据带宽上受到限制,并且在苛刻的工业环境中的长距离并不总是支持,并且通常需要单独的电缆才能获得电源。

基于100Base-TX/10BASE-T的现有工业以太网解决方案可提供高达100 MB的高数据带宽,并在CAT-5或CAT-6E电缆上使用电源(POE)(POE)。但是,它们仅限于100米,并且不支持有害区域用例,因为它们是高功率解决方案。

Condition-monitoring applications require support for potentially remote sensors that require robust communication over a long distance, where the sensor node is in a space- and power-constrained IP66/IP67 enclosure due to the harsh industrial environment it’s deployed in. These constrained sensor-node applications need a low-power, high-data-bandwidth communications solution that delivers both power and data on a low-cost, easy-to-install cable with a small cable connector to the sensor node.

单对以太网的新连接

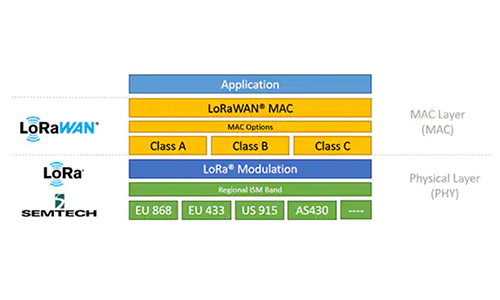

IEEE开发的新的单对以太网(SPE)物理层标准正在提供新的连接解决方案,用于传达用于状态监控应用程序的资产健康见解。10BASE-T1L是一种新的以太网物理层标准(IEEE 802.3CG-2019),在2019年11月7日获得IEEE批准。它将通过通过无缝的以太网连接到现场级别来显着提高运营效率,从而极大地改变自动化行业资产。

10BASE-T1L解决了迄今为止限制以太网对现场资产的使用的挑战。这些挑战包括功率,带宽,电缆,距离,数据岛和本质上安全的区域0(危险区域)应用。通过解决Brownfield升级和新的Greenfield安装的这些挑战,10BASE-T1L将启用新的资产健康见解,这些洞察力以前是不可用的,并将它们无缝地传达给控制层和云/私人服务器。这些见解将通过从现场资产到云或专用服务器的收敛以太网网络来唤醒数据分析,运营见解和生产率的新可能性(图2)。

Advantages of 10BASE-T1L Ethernet Connectivity

10BASE-T1L消除了传统通信需要连接到控制和管理网络所需的复杂,耗电的网关的需求。它还可以在信息技术(IT)和操作技术(OT)网络中启用融合的以太网网络。收敛的网络提供简化的安装,简单的设备更换以及更快的网络调试和配置。这会导致更快的软件更新,并通过简化的根本原因分析和现场级资产的维护。

The 10BASE-T1L physical layer combined with messaging transport protocol (MQTT) provides a messaging protocol for field assets with a low memory footprint for lower-power smart sensors. MQTT provides direct connectivity of asset health insights to the cloud or a private server for advanced data analytics for predictive-maintenance techniques.

要与启用10BASE-T1L的现场资产进行通信,需要具有集成中型访问控制(MAC)的主机处理器,被动媒体转换器或具有10Base-T1L端口的开关。不需要其他软件,特殊驱动程序或定制的TCP/IP堆栈(图3)。这为10Base-T1L设备创造了明显的优势:

- 10BASE-T1L是一种非常低功率的物理层技术,可以通过高数据频道连接解决方案实现非常低的智能传感器部署。

- A smart sensor connected with 10BASE-T1L is accessible over the network and can be remotely updated anywhere, at any time. As sensors become more complex, it increases the probability of software updates. Updates are now possible within realistic periods of time via a fast Ethernet connection.

- 访问高级以太网网络诊断工具以简化根本原因分析。

- 通过单个扭曲的电缆及以后的单个扭曲配对电缆提高了智能传感器安装的灵活性,并在单个扭曲对准电缆上具有功率和数据。

- 资产健康见解往往是远程的,via a web server running on the field asset, reducing the need for a maintenance technician to walk the floor to monitor an asset’s health—a significant cost saver.

10BASE-T1L:两根电线上的电源和数据

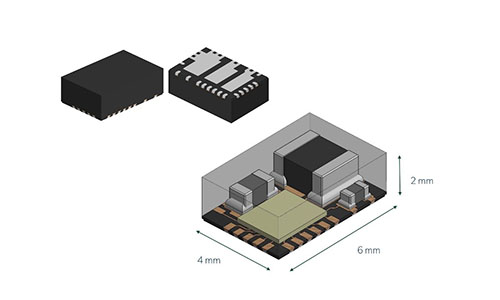

对以太网(SPOE)或工程功率体系结构与10BASE-T1L PHY相结合的单配对功率可在单个扭曲的配对电缆上提供出色的功率和数据。例如,Adin110010BASE-T1L PHY developed by Analog Devices enables lower-power Ethernet connectivity on a single twisted-pair cable that’s over 1000 m with only 39 mW of power consumption.

A 10-Mb data bandwidth communication link with significant power capability over the same cable enables smart sensors with the power and connectivity bandwidth to support new condition-monitoring applications. With 10BASE-T1L connectivity, asset health insights are now more accessible as the insights are available across a converged IT/OT Ethernet network.

10BASE-T1L supports hazardous-area use-case applications (Intrinsically Safe Zone 0) for process automation deployments and is sometimes referred to as Ethernet-APL. 10BASE-T1L/Ethernet-APL will enable new lower-power solutions to connect asset-health-monitoring smart sensors to the higher-level data-management systems. This will enable AI and advanced analytic systems to transform asset health data into actionable insights and deploy new predictive-maintenance services.

系统级解决方案和AI平台,以加快条件监控部署

适用于条件监控应用程序的完整的系统级解决方案将是实现高质量数据和见解的关键,从而大大改善了制造过程。10BASE-T1L/以太网APL的进步,再加上实时的AI驱动传感技术,例如Adi Otosense,可以在所有级别的客户系统中启用AI集成。

Adi Otosense平台感知并解释了任何声音,振动,压力,电流或温度,以提供基于连续的,基于条件的监视和按需诊断。它实时在线和离线实时在边缘的现场资产上运行。Otosense系统可检测异常,并通过与条件监控域专家的互动进行学习,同时创建数字指纹以帮助识别机器中的故障。结果,它可以在造成昂贵的停机,损坏或灾难性失败之前预测崩溃。

Advances in sensing, signal processing, connectivity, mechanical packaging techniques, and artificial intelligence at the edge are enabling new condition-monitoring solutions and predictive-maintenance services that will usher in significant savings and productivity improvements.

针对条件监控应用程序的新系统级解决方案将包括用于振动和冲击检测的MEMS传感器,用于数据获取的精确转换器技术以及用于创建高质量资产健康数据的Edge处理。低功率,强大的有线和无线通信解决方案可从资产中访问资产健康数据。

无线通信解决方案包括SmartMesh或无线HART。在有线通信解决方案中,有RS-485和10Base-T1L单对以太网,可在两条电线上提供功率和数据。这些技术以及高性能电源管理结合在资产监控解决方案(例如Otosense技术)中,它们是完整的硬件和AI监视解决方案,可以安装在设备上以进行预测性维护(Fig. 4)。

要了解有关条件监控应用程序的完整,系统级解决方案和人工智能产品的更多信息,请访问Analog.com/cbm。

参考

1.“”The Costs and Benefits of Advanced Maintenance in Manufacturing。” U.S. Department of Commerce, April 2018.

.jpg?auto=format,compress&fit=crop&h=139&w=250&q=45)