消费电子产品的制造商正面临着不断增加的压力,即设计时尚,紧凑的设备,客户垂涎,平衡形式和功能,以在拥挤且竞争激烈的市场中区分其产品。没有什么比在智能手机市场上更真实的地方,在智能手机市场上,企业命运可以随着他们最新一代手机的成功而兴起。

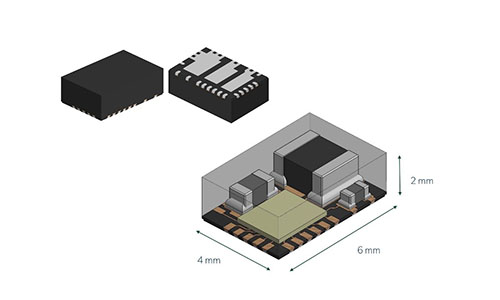

When it comes to smartphone designs, every millimeter of space savings achieved within the device enclosure can unlock significant value for the end customer. It makes possible the use of larger, higher-resolution displays, bigger batteries, and more sophisticated processors and components. All of this enhances the device’s feature set, and improves the overall user experience.

这些形式因素驱动的设计压力部分通过增加高密度互连(HDIS)的使用部分缓解,这比传统的印刷电路板(PCB)启用了单位面积功能更多的功能。HDI在智能手机及其嵌入式子系统的持续微型化中发挥了至关重要的作用。

但当我们从下一代4 g LTE, 5G-compatible smartphones, the PCB industry’s approach to HDI manufacturing must also evolve. Massive-MIMO (multiple-input multiple-oOutput) antenna configurations and increasingly complex RF front-ends will expand the RF content footprint within the 5G smartphone, and the processing power needed to support the staggering volume of 5G data will likely impact battery capacities and geometries, among many other factors. As a result, despite increased I/O demands, the amount of available space for HDI PCBs within 5G smartphones will be significantly reduced.

此外,5G固有的较高频率将需要更严格的阻抗控制。如果没有以极高的精度形成,那么较薄的HDI痕迹会引入信号降解和数据融合失误的风险增加。

Addition and Subtraction

PCB制造商可以利用改进的半添加过程(MSAP)来克服这些挑战。MSAP在当今通常在IC底物生产中使用,有望在先进的HDI PCB制造业中广泛采用。

Current line/space requirements have already reduced to 30/30 and are expected to decrease even further to 25/25, or even 20/20. mSAP is fully able to support these requirements, enabling 5G smartphone makers to achieve unprecedented device densities while leveraging superior conductor geometries for exacting impedance control at high-frequency operation.

MSAP本质上是常规减法过程的相反(如果愿意的话),或反向图像。在减法过程中,通过用蚀刻抗性涂层铜层形成细纹,将光刻摄影施加图像应保留铜的区域,并蚀刻未成像的材料。

这种方法的主要缺点是,用于垂直蚀刻的化学处理也将沿着痕量壁的水平方向溶解铜。在横截面视图中,所得的痕迹将在形状上显示出梯形。这种楔形的轨迹会引入无数的阻抗异常,并且在形成线比预期的范围更宽的情况下,电路密度损害。

相比之下,使用MSAP,将更薄的铜层涂在层压板上,并在不施加抗性的区域镀上,这是该工艺的“添加剂”性质。然后将剩余在导体之间空间中的薄铜蚀刻。尽管痕量几何形状是在减法过程中化学定义的,但MSAP允许通过光刻造影定义痕量几何形状。因此,在直垂直线中形成痕迹,以更高的精度形成,产生矩形形的横截面,可最大化电路密度,并在信号损失较低的情况下实现准确的阻抗控制。

The rectangular shape enabled by the mSAP process is far more effective, maximizing circuit density and accurate impedance control with lower signal loss.

高级制造技术

MSAP将帮助PCB制造商克服5G智能手机高级HDI生产的技术障碍,但最终必须以最小化成本并最大化生产吞吐量和产量的方式实施MSAP,以确保足够的投资回报。尽管IC底物的生产可以舒适地吸收通常与MSAP相关的较高成本,但智能手机PCB制造的商业体积量表涉及成本和生产效率的宽容远不那么宽容。

To effectively employ mSAP in mass production, PCB suppliers are increasingly investing in the advanced manufacturing tools and techniques necessary to maintain and extend their competitive advantage through the transition from 4G LTE to 5G smartphones. In this scenario, HDIs with higher densities and precisely formed lines will be a critical requirement.

These PCB manufacturers are adopting advanced direct-imaging (DI) systems capable of achieving 10-micron lines and 15-micron line spacing, with high registration accuracy down to 7.5 microns to ensure precise uniformity. These capabilities can encompass advanced localized-registration features designed to enable the registration of partitions within the individual PCB.

配备高度焦点(DOF)和多波长光源的DI系统可以在各种抗拒的情况下产生更清晰的边缘图案,同时保持高吞吐量,高质量和一致的均匀性。

利用高级自动化 - 光检查(AOI)系统,PCB制造商可以快速而准确地识别HDI缺陷以提高质量保证,并减少可能停滞生产过程的错误警报。此外,可以使用2D计量评估功能来实现顶部和底部导体宽度的连续自动内联测量,从而确保使用简化的采样技术确保准确且可重复的测量,并启用改进的阻抗控制。

Where appropriate, PCB manufacturers may also employ automated-optical-shaping (AOS) systems to eliminate defects such as opens, nicks, and shorts. Using 3D-shaping capabilities that recreate the original design, AOS systems can be applied to inner and outer HDI layers. Whereas manual repair is less accurate and can cause damage to the panel, AOS enables highly precise, high-quality shaping, boosting yield considerably while virtually eliminating PCB scrap, thereby creating a competitive cost structure for the end client.

理想情况下,这些先进的HDI制造解决方案应通过软件框架捆绑在一起,该软件框架在整个生产过程中收集数据,以确定在每个接触点如何处理PCB的何时,何时以及如何处理。这可以有助于确保可能需要进行质量检查故障排除的场合端到端HDI可追溯性,同时为制造工作流提供整体视图。

The evolution of 5G smartphones demands a new approach to advanced HDI manufacturing that maximizes the density of onboard embedded electronics while reducing RF signal friction at high frequencies. mSAP is making it possible for PCB suppliers to meet these exacting requirements, while leveraging DI, AOI, and AOS technologies to help lower manufacturing costs, accelerate production throughput, and maximize yield.