>>电子设计资源

。。>> Top Stories of the Week

.. .. .. >> CES 2021

您将学到什么:

- 无线电池管理系统(WBM)消除了传统有线线束系统的机械挑战和成本。

- wBMS weigh less and take up less space than harnessed batteries.

- WBM可为每个电池提供最大的能源利用,每次充电更多英里。

- 德州仪器has joined Analog Devices among other semiconductor suppliers offering wBMS.

归零地在战争中赢得民心of EV engineers today is squeezing more range out of battery packs. Steady advances in battery-cell monitoring ICs have enabled higher energy density and increased life and reliability from packs that can stack up to 800 V or more to support the loads of the ac motor. To accommodate the large quantity of cells required, packs are distributed throughout available spaces in the vehicle. A电池组可能位于前面,乘客舱室的下方或车辆的后部。

The capacity of lithium-ion cells diminishes over time and usage, so every cell in a system must be managed to keep it within a given state of charge (SOC).电池通常由模块(单元组组)组织,该模块由专用的电池管理电路(BMIC)管理,该电池(BMIC)监视并调节能量和性能。BMIC的主要作用是定期测量细胞电压和温度。通常,一个BMIC可以监视多达16个连接的单元。

A wired battery-management solution, however, has several challenges associated with detecting failures. Among them is the cost of repair and bulky cables weighing anywhere between 75 pounds on the low end to about 150 or even 200 pounds.

All of that wiring takes up space and is also a drag on reliability, range, maintenance, and overall cost. But what if the battery-management system could be controlled without pounds of wiring?

WBM的好处

Wireless battery-management systems (wBMS) can monitor battery packs continuously for state of health (SOH) and SOC and promise to further improve safety and reliability of the full battery system. By improving the battery-management system by going wireless, the reduced weight of the system allows for more energy efficiency, and thus increases the driving range of the car with the same charge.

On top of that, the wiring harness and connectors are quite a common source of cable failures。Wireless BMS should reduce end-user repair costs since they eliminate the physical harnesses and wires. Maintenance also becomes easier by enabling the replacement of a battery module instead of replacing the workings of the complete battery.

由于集成的硬件和系统软件可以跨多个车辆平台扩展,但具有最小的变化,灵活的无线解决方案会大大降低工程成本。此外,为每辆新车开发特定的通信系统或重新设计复杂的布线方案而不需要时间。

An ASIL D-Qualified wBMS

德州仪器(TI)推出了一种针对无线BMS的解决方案,该解决方案具有独立评估的功能安全概念,该概念可实现ASIL D. TI的解决方案,展示了车辆设计师如何删除重型,昂贵,可维护的电缆并提高电动汽车的可靠性和效率。

The TI development follows an模拟设备公告去年秋天wBMS for production electric vehicles that will debut on General Motors’ production vehicles powered by its Ultium batteries. Because it has no cables, it will adapt to different vehicles without the need to be redesigned. GM plans to launch as many as 20 electric vehicles, using all of its brands, by 2023. These batteries will have a capacity between 50 and 200 kWh.

ADI和TI无线网络均基于2.4-GHz技术。迄今为止宣布的两个系统可为每个电池提供最大的能源利用,每电荷增加了更多的英里,它们支持安全可持续的零铜电池化学分配,例如磷酸锂(LFP)。

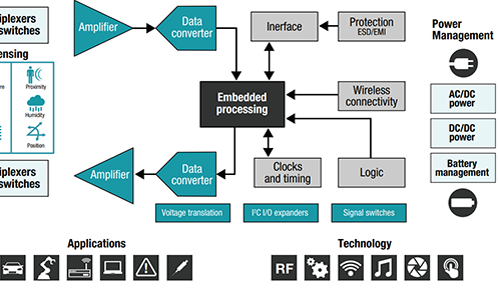

TI的无线BMS产品包括SimpleLink 2.4-GHz CC2662R-Q1无线微控制器(MCU),这是一种符合AEC-Q100的ARM Cortex-M4无线MCU,可针对低功率,扩展温度范围和增强的安全性优化。CC2662R-Q1设备运行专有的无线协议,可以在主机系统处理器和BQ79616-Q1电池监视器和平衡器之间进行数据交换。

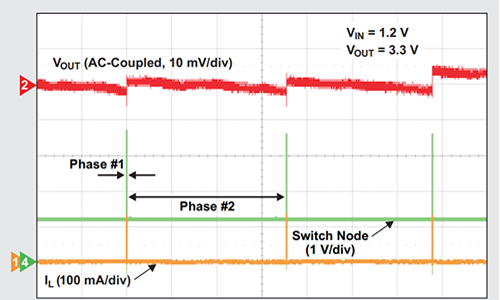

The system sends data from the battery controller unit to the self-supervision unit and vice versa at 1.2 Mb/s while also guaranteeing a latency of around 2 ms for the best-case scenario for a node. It communicates inside a metal box—a Faraday cage—that shields the frequency used for transmission to the outside world from interference. The TI solution supports up to 100 nodes. Each node is connected to a battery monitor like the BQ79616, which is a 16-channel device.

TI believes it has the industry's lowest-power-consumption wBMS because of the combination of frequency hopping and time-duration multiplexing. Furthermore, you're able to recycle the nodes to wake up only when necessary to transmit and then go back to sleep while still maintaining a synchronous connection.

BQ79616-Q1电池监视器和平衡器包括获得专利的唤醒功能。与BQ79600-Q1 SPI/UART通信接口配对时,当车辆停放或关闭时,可以使系统关闭。这有助于设计工程师节省电池电量,改善电池平衡并支持安全要求。

其他功能包括细胞平衡,一种集成的模数转换器(ADC),多电池支持,开放线检测,过度振动保护,过电压保护,温度传感,自能力保护,电压欠压保护和-40至125的工作温度范围°C。

In terms of signal measurement accuracy the part is said to deliver cell-voltage measurements with less than ±2 mV of error和网络数据包的错误率小于10-7。

TI要求功能安全机构TüvSüd独立评估定量和定性错误检测性能以及使用TI的无线BMS功能安全概念的ISO 26262认证的ASIL D级ASIL D(ASIL 26262认证)的可行性。

The 16-channel BQ79616-Q1 is available now in a 10- × 10-mm, 64-pin thermally enhanced thin quad flat package (HTQFP). The BQ79600-Q1, available in volume production, comes in a 16-pin thin shrink small-outline package (TSSOP).

预计新的12和14通道电池监视器和平衡器将在2021年第一季度提供。

ADI带着WBMS进入竞争

实施类似物Devices’(ADI) wBMS also eliminates the traditional wired harness, saving up to 90% of the wiring and up to 15% of the volume in the battery pack, without compromising range and accuracy. The ADI measurement ICs use sigma-delta ADCs. With a sigma-delta converter, the input is sampled many times during a conversion and then averaged. The result is built-in low-pass filtering to eliminate noise as a source of measurement error.

ADI的WBM包括所有集成电路,硬件和电源软件;电池管理;RF通信;系统在单个系统级产品中发挥作用,该产品支持ASIL D安全性和模块级安全性。通过为车辆的寿命提供高精度,该系统可为最佳车辆范围所需的每个单元提供最大的能量利用。而且,如前所述,它支持LFP等安全可持续的零电池电池化学。

Additional system features enable batteries to measure and report their own performance, increasing early failure detection and enabling optimized battery-pack assembly. The data can be monitored remotely throughout the battery lifecycle—from assembly to warehouse and transport through installation, maintenance, and into a second-life phase.