A new software tool simulates the spots on a circuit board where processors and components are likely to fall off or become dislodged from vibrations that automobiles, airplanes, or satellite systems might go through, so that engineers can find issues earlier and improve the reliability of their products.

本星期,Mentor Graphics在其Xpedition软件环境中添加了一个软件工具,以在振动和加速分析过程中更早地将电气工程师和布局设计师绑起来,这通常由机械专家或测试实验室处理。

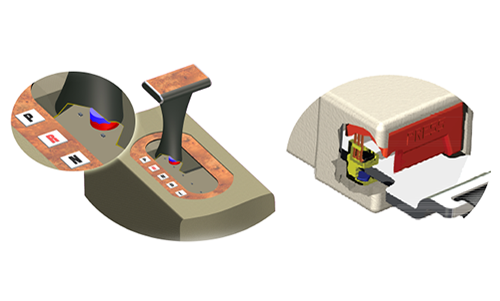

In a demonstration, the software applies stress to the virtual board and highlights for engineers the areas based on failure probability. Components that are a high-risk are red, while lower risk areas are yellow. Zooming closer into the pins holding down the parts, where failures often occur, shows a similar pattern of stress.

Normally, a company will rent out space in a testing lab with a shake-and-bake machine that tests devices until they fail. These physical tests are known as HALT, or highly accelerated lifecycle testing. But these types of tests costs thousands of dollars, the process is lengthy, and results may vary.

This type of testing is typically done before manufacturing, so getting it right is essential. And an extra layer of security is also helpful since failures can be costly – fixing the electronics in a single car is one thing, but having to do a recall to fix them all is different.

That has been supplemented with mechanical analysis software that mechanical engineers start using before sending a product or part off for physical testing, but that provides only basic understanding of where vibrations or acceleration can ruin boards.

“On a mechanical tool, the parts would be boxes and cylinders with no intelligence,” said David Weins, a product manager atMentor Graphics, talking about how processors or capacitors. But the new tool adds an extra layer of detail to what mechanical specialists know about possible failures.

他说:“我们想将验证和验证直接带到零件旁边的位置,以便更快地开始固定过程。”向机械专家。

Last year,Mentor Graphicsagreed to be acquired by Siemens, which said it planned to fold the software makers into its part of the product life cycle management software unit. The group sells software to help companies manage the life-cycle of a product, from design and production to service and disposal.

The new software dovetails with the idea that electrical and mechanical engineers are collaborating more closely with each other on electrifying and smartening up mechanical designs. The Xpedition software is designed for big teams working on big products, and with the new tools the electrical engineers can hand off the board design having identified all the obvious failure points.

Xpedition软件包含一个超过4,000个唯一的3D组件模型的库,这些库用于创建高度定义的零件以进行仿真。它可以在物理测试期间通常会固定木板或产品的螺钉,垫圈和夹具。设计人员可以将两个维零件进口到3D环境中。

该公司表示,新工具在小时内预测了93%的失败组件,而每个身体停顿为三到五天。Weins说,该软件可大大降低测试成本和输出通过/零件的失败。

The program can detect components on the threshold of failure that would be missed during physical testing. It can also analyze pin-level Von-Mises stress and deformation to determine failure probability and safety factors. This results in increased test coverage and shortened design cycles to ensure product reliability and faster time to market.

他补充说:“我们要驾驶的是首次右翼设计。”“我们不是在试图替代停止测试或机械分析。”