您将学到什么:

- IPC标准,用于更好的PCB制造和组装。

- IPC标准的优势。

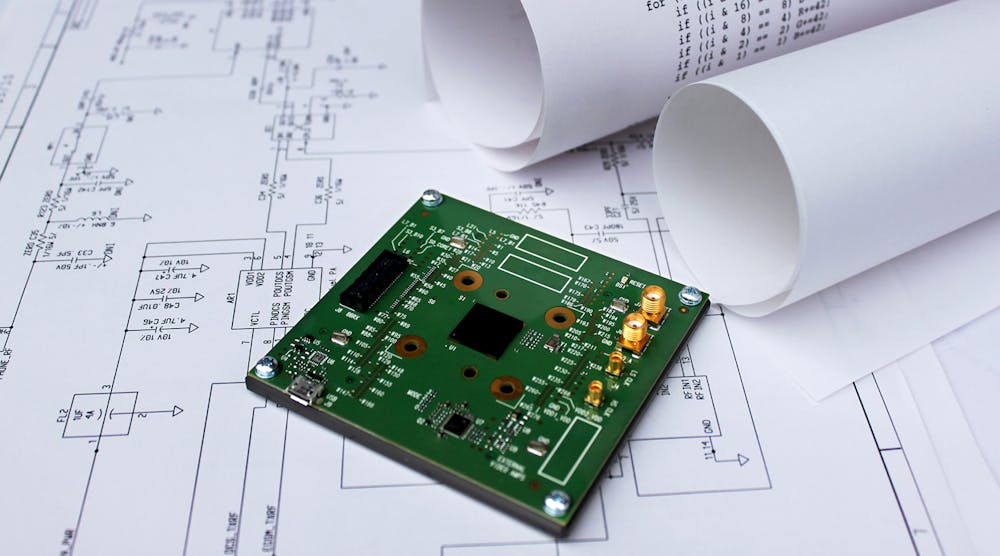

这印刷电路学院(IPC)is as known as the Association Connecting Electronics Industry. It’s a trade association for the electronic interconnection industry that authorizes high-quality electronics by developing the standards to drive the success of the global electronics industry.

IPC最初由六家PCB制造商于1957年建立,现在由3,000多家公司组成,这些公司设计,制造和组装PCB,用于从消费电子和汽车到电信和医疗保健的应用。IPC成员来自电子行业的不同方面,例如原始设备制造商(OEMS),PCB制造商,PCB assemblyservice providers, and suppliers.

IPC与电子行业合作,确定行业挑战,并与其成员合作提供合适的解决方案。它还收集了与电子制造行业有关的最新数据,并概述了最佳实践的适当标准。

IPC制定的标准适用于PCB生产的每个阶段,从设计到制造到最终组装。开发的各个阶段都有可接受性标准,以确保高质量的最终产品。IPC标准的一些关键要点包括:

- 这terms and definitions used in the standards are listed in the IPC-T-50 document.

- IPC-2581和IPC-2610系列中列出了文件格式,产品文档和设计软件的标准。

- 这design and land patterns are covered in standards like IPC-2221, 2222, 2223, and 2226 as well as IPC-7351.

- 预计PCB的底物和基础材料将符合IPC-4101、4103、4104、4202、4203和4204中提到的标准。

- IPC-6011、6012、6013、6017和6018中概述了印刷板质量和可靠性标准。

- Printed-board acceptability standards are described in IPC-A-600.

- Requirement criteria for soldered electronic assemblies are listed under IPC-J-STD-001, IPC-HDBK-001, and IPC-AJ-820.

- 电子组件的可接受性标准在IPC-A-601下概述。

- Cable and wire harness assemblies have the requirements and acceptance standards elaborated in IPC/WHMA-A-620, IPC-D-620, and IPC-HDBK-620.

- 这acceptability standards for manufacturing, inspection, and testing of electronic enclosures are covered under IPC-A-630 and IPC-HDBK-630.

- 也有高级包装,存储和处理的标准。

Some of the IPC standards relevant to PCB design and manufacturing include:

- IPC-1752A establishes a standard reporting format for material declaration data exchanged among the designers, distributors, and manufacturers. It also supports reporting of bulk materials, components, assemblies, and products.

- IPC-2152 defines the current carrying requirements in copper traces and planes in a PCB design.

- IPC-2221 prescribes some generic design and performance requirements in PCBs and other methods of component mounting or interconnecting structures.

- IPC-2581 specifies a generic requirement for sharing information among supply-chain participants. It provides a standard format for exchanging design data that ensures reliable production outcomes.

- IPC-4101 covers requirements for a wide range of PCB laminates or prepregs used to build stackups.

- IPC-4761 reflects the design guidelines for via protection to ensure dependability, manufacturability, and quality.

- IPC-A-600系列定义了印刷电路板的可接受性标准,以及各种PCB组件的三个标准IPC类:

- Class 1:This includes consumer electronics and general products that are assembled at the cheapest possible price and expected to function for a set duration。

- 第2类:Under this category, products like laptops or home appliances are included. They are service-oriented products with dependability and an extended lifetime.

- 第3类:医疗设备和航空设备等关键性能电子产品适合此类别。预计他们将在苛刻的环境中不停地操作,要求非常高的可靠性和鲁棒性。IPC-7351指定了表面安装(SMT)组件的足迹和土地图案要求。SMT PCB组件提供者在设计土地图案时遵循这些规格,以确保焊接性和可靠的电连接。

IPC标准纳入了设计指南中,可以在整个开发过程中使用有效的清单进行验证。现在,客户更喜欢保证用户安全以及高性能的产品。因此,遵守IPC标准应证明PCB产品具有出色的质量。

好处Derived from IPC Standards

IPC standards bring several benefits to the electronics industry, such as:

- Enhanced product value and consistency:Strictly following the IPC standards throughout the development and manufacturing process leads to a high-quality product, further improving product reliability and customer satisfaction. IPC standards hence contribute to the consistency and overall product value in the market.

- Better communication among contributors:当涉及到的所有成员遵循相同的我PC standards, it becomes easy to communicate between the groups. The common jargon assists in the clear interpretation of set standards for each deliverable and avoids any ambiguity during communication.

- Improved brand identity in the market:Following IPC standards helps build your brand value and sets a good reputation in the market. It indicates the commitment of the manufacturer toward product quality. This can bring in more collaboration and opportunities to expand your business.

- 更低的花费:Adhering to the IPC standards can help a manufacturer improve supply-chain efficiency, which can further reduce the resource requirements. And it will substantially lower production cost.

- 无缝工作流程:When all team members diligently follow IPC standards, it also significantly reduces the possibility of faults and delays. This leads to a smooth flow in the development, production, and assembly lines of a PCB product.

上述优势证明了IPC标准对PCB的重要性,并且对任何PCB制造商和合同制造商(CM)确实很重要。

经验丰富的CM不仅会关注与集会有关的一些细节;相反,他们根据IPC标准组的完整集将整个过程与强大的基础整合在一起。结果,CM甚至可以识别组装线中的PCB制造缺陷,并提高生产率。与经验丰富的CM合作为建造高质量的PCB产品提供了另一条途径。