您将学到什么:

- 为什么Emxos虽然不及OCXOS,但对于太空系统开发人员来说是一种吸引人的替代方案。

- How EMXOs help developers maintain the same level of performance as an OCXO in a smaller, lighter package while significantly reducing power consumption.

太空任务将电子组件暴露于各种恶劣的环境中。在忍受了发射的冲击和振动之后,组件必须可靠地在宽温度波动的情况下可靠地提供15年的额定性能。对于晶体振荡器,其他要求包括作为极其精确且稳定的频率参考,同时在最小的包装中消耗最小的功率。这是一项主要由烤箱控制的晶体振荡器(OCXO)填充的五个顺序。

但是,最近的一类组件(撤离的微型晶体振荡器(EMXO))使材料相等甚至更高的性能和更强的坚固度,而较小的功耗则减少,以及其他优势。因此,EMXO日益普及的人不足为奇。

小而强大

水晶oscillato使用的石英晶体r may seem mundane, but it’s a precision piezoelectric component machined to stringent tolerances. Adjusted to vibrate at a specific frequency, it maintains a high degree of stability owing to its inherently high Q value.

However, crystals are very sensitive to even small changes in temperature that cause their frequency to vary. These variations can be tolerated for some applications, but that’s not the case for many others. The temperature-compensated crystal oscillator (TCXO) was designed to mitigate this problem by adding a temperature-sensitive reactance circuit in its oscillation loop, but the resulting level of improvement may be insufficient for more demanding applications.

可以通过将晶体放入小烤箱中,从而产生OCXO来实现稳定性的高度改善。也就是说,在典型的OCXO中使用的烤箱是一种相对渴望的装置,使其更大且更重。这种增加的功耗可能是太空飞行的重要问题,在其他应用中最小化的大小和重量至关重要。

The EMXO was created to deliver the same level of performance as an OCXO but in a smaller, lighter, hermetically sealed package while significantly reducing power consumption—key factors in spaceflight applications.微芯片技术EX-219是最新的EMXO设计的一个很好的例子,该设计具有性能特征桌子。

EX-219specification parameters for stability, power consumption, and environmental conditions show suitability for spaceflight applications including RF transmitter/receiver, GPS guidance, and reference oscillator.

The development of EMXOs took many years, but the results were well worth the effort. While an OCXO uses insulation of low thermal conductivity to minimize power consumption, an EMXO employs a vacuum as the insulation method. It produces a contamination-free vacuum level of 10-6托尔并将绝缘重量减少到几乎一无所有。焊缝,灰尘或蒸气没有污染,这种极高的真空水平随着时间的流逝而减少。无污染的环境还有助于使用开放的水晶空白而不是更大的包装类型,从而进一步降低了尺寸和重量。

结果,EMXO的内部质量可以比典型的OCXO小,转化为烤箱加热和较低功耗的体积较小。由于EMXO被疏散并且比OCXO的热量要少得多,因此其热身时间要快得多。此外,晶体空白集成在混合包装中。这有助于减小尺寸,使EMXO的包装中的包装不到典型OCXO的一半。

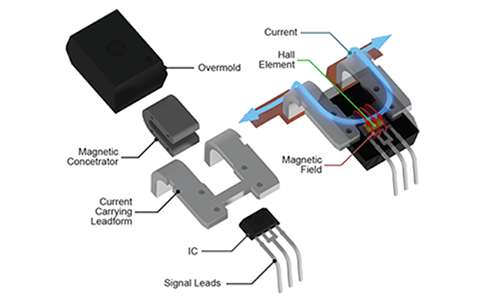

EMXO电路由加热的底物(烤箱)和输出基板组成。使用应力补偿,双重旋转的晶体(SC/IT切割)会导致良好的相位噪声,衰老速度较慢和G-敏感性降低。晶体具有四点安装结构,可用于坚固性和低g敏感性。

由于使用合成扫掠石英,EMXOS获得了更高的辐射耐受性。热绝缘结构在其工作温度范围内保持了几乎恒定的温度。不需要热隔离的输出基材直接安装在外壳上(图。1)。

1. EMXO由安装在基板上的烤箱和输出组件组成。烤箱基板组件安装在热绝缘僵局上,以最大程度地减少热量损失,并将输出组件安装在标题平台上。晶体具有四点安装座,整个过程都采用了混合构造。

1. EMXO由安装在基板上的烤箱和输出组件组成。烤箱基板组件安装在热绝缘僵局上,以最大程度地减少热量损失,并将输出组件安装在标题平台上。晶体具有四点安装座,整个过程都采用了混合构造。

克服EMXO泄漏率测试挑战

EMXO的许多优点是其泄漏率,该泄漏率太低(1×10-12atm·cc/s helium) that it’s outside the range of the equipment intended to measure it. The EMXO enclosure is sealed using cold welding, which creates a metallurgical bond between the metal surfaces without adding heat during the sealing process. That said, leakage can be a significant issue with hermetically sealed packages.

政府太空机构需要包装设备以满足通过细肠测试确定的泄漏要求。但是,由于EXMO的泄漏速率低于商业仪器的测量,因此,使用军事规格规定的太空传播电子组件规定的标准基于氦气的方法,EMXO不可能进行泄漏测试。应当指出的是,即使在太空中撤离包装的泄漏率并不显着,但这是一个重要的考虑因素,而仍然存在。

Hermetic packages are typically sealed using resistance welding or seam welding, and they’re usually backfilled with a mixture of a noble gas and helium as a tracer at a pressure of about 1 atmosphere. This makes it possible to detect a leak rate between 1 × 10-10and 1 × 10-9ATM·CC/S使用1×10分辨率的商业仪器-8ATM·CC/s。

氦气炸弹是一种常见技术,用于衡量EMXO等疏散外壳的泄漏率。在此测试期间,在泄漏测试之前,将少量的氦气注入密封包装中。但是,一个缺点是氦气可以扩散并渗透到包装的金属和玻璃中。在细肠检测过程中,可以从金属或玻璃中释放氦气,从而导致悲观的泄漏率。该过程称为解吸,可以诱导1×10的明显泄漏率-9ATM·CC/S氦气。

由于EMXO中的烤箱是按比例控制的,因此其功耗与从烤箱到振荡器外壳的热电阻成反比。也就是说,烤箱绘制电流以保持几乎恒定的温度。

In operation, heat flows from the oven to the case through three heat-transfer mechanisms: convection, conduction, and radiation. Conduction and radiation are influenced by the materials and the construction of the package. Because these are stable properties, they have an insignificant effect on changing the oven current.

由于内部包装压力的变化会影响EMXO中对流的热流量,因此内部压力较高的泄漏单元将固有地吸收更多的电流。这允许使用简单仪器检测到非常低的泄漏水平 - 如果真空由于泄漏很小而降解,功耗将大大增加。

Microchip利用了功耗和内部压力之间的关系,开发了一个高准确的过程来确定EMXO软件包的密封完整性,并使其能够有资格用于空间应用。已经对EX-209/245进行了分析以验证该过程。1结果表明,使用烤箱电流测量密封完整性的测量可以以1×10的泄漏速率筛选零件-6,1×10-7, and 1 × 10-8ATM·CC/S氦在几分钟内,几个小时和密封后几天。

The EMXO maintains its stability even when the internal package pressure increases to as high as 1 torr, so it would take up to 70 years for the EMXO’s internal package pressure with a leak rate of 1 × 10-12atm·cc/s helium to reach a low vacuum of 0.1 torr(图2)。If a 1 × 10-11ATM·CC/SEC氦气泄漏率和0.5-TORR内部包装压力是为了保守的安全边缘,最新的EMXOS可以实现15年的运行寿命。

2.该图以各种泄漏速率显示了EX-219的内部包装压力。请注意,内部封装压力将需要70年的时间才能以1×10-12 cc/s氦气达到0.1 TORR。

2.该图以各种泄漏速率显示了EX-219的内部包装压力。请注意,内部封装压力将需要70年的时间才能以1×10-12 cc/s氦气达到0.1 TORR。

概括

The EMXO may be less well known than its counterparts for use in space, but it offers significant improvements that together make it an appealing alternative. Although the fact that it uses a vacuum as its main differentiator, construction techniques such as cold welding and hybrid construction also significantly contribute to the result. For these reasons, the EMXO has been used in many spaceflight applications for over a decade, and as it gains recognition, it’s likely that many more are in the wings.

Reference

1。“Using Oven Current Instead of Fine Leak Detector to Screen Seal Integrity of EMXO Cold-Weld Evacuated Package,” Hoklay Pak, Microchip Technology, March 2021.