What you’ll learn:

- 什么是声学微型成像?

- How the Nordson Sonoscan AMI tool images IGBTs, stacked wafers, and flat-surface items.

声学微型成像(AMI)用于筛选或分析绝缘的栅极双极晶体管(IGBT),翻转芯片,动力设备,球网阵列(BGA),陶瓷芯片电容器和许多其他组件类型。扫描的目的是创建一个内部特征的声学图,以识别结构缺陷,而无需物理打开组件。缺陷通常是充气裂缝或空隙。颜色将揭示缺陷的深度。

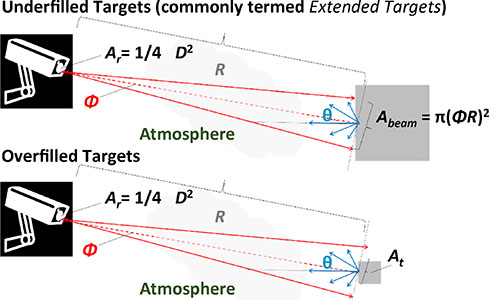

The transducer of an AMI tool scans horizontally just above the surface of a multilayer electronic component. It fires a very brief pulse of ultrasound downward through the 3-mm layer of water that enables the pulse (which doesn’t travel through air) to reach a single tiny x-y location on the top surface of the component. The pulse travels through the 3 mm of water at about 1498 meters per second, so this step takes about 2 µs.

When the pulse strikes the water-to-solid interface, a portion of its energy is reflected back toward the transducer. There, its arrival time is noted and the distance from the transducer to the water/solid interface is calculated and saved as a reference for subsurface inspection.

At every x-y position, the portion of the pulse that’s not reflected travels deeper into the component, where it may be reflected by additional material interfaces. The moving transducer performs the whole operation—launching pulses and receiving echoes—tens of thousands of times per second. Each pulse/echo will provide one colored pixel for the acoustic image.

Ultrasound

Ultrasound isn’t reflected from the bulk of homogeneous materials, but rather from the interface between two different materials. A pulse striking an interface sends back an echo whose amplitude is determined by the relative acoustic properties of those two materials. If the two materials are both solids, the percent of the pulse’s energy reflected may be from a few percent up to about 60%.

The non-reflected part of the pulses’ energy crosses the interface and travels deeper into the component, where it may be reflected from interfaces between deeper materials. But if the second material is air, the pulse is virtually 100% reflected back toward the transducer. None crosses the solid-to-air interface.

IGBT Imaging

图1shows how theNordsonC-SAM声学微型成像工具可以成像IGBT,以找到可能导致使用过程中电气故障的空隙和其他缺陷。Sonoscan技术人员指出,用户将避免扫描IGBT的顶部表面,因为即使是水耦合留下的残留物也很小,在操作过程中也可能造成损坏。

However, an inverted version of C-SAM pulses ultrasound into the heatsink on the bottom surface of the IGBT to generate echoes from various internal interfaces. The red lines in图1标记接收到成像的大门的顶部和底部。从较高和较低深度反射的回声被忽略。

请注意大门图1begins just above the heatsink-to-solder interface, because echoes from this interface would have no useful information. But it ends just above the solder-to-raft interface to pick up all of the raft’s contours.

Within the solder layer, a single void is shown above an arrow representing an echo reflected from the solder-to-air interface. The pulse striking the void is reflected as an echo whose arrival time at the transducer reveals the depth of the void.

The IGBT shown in图2使用Nordson测试和检查的C-SAM工具的30 MHz传感器以这种方式成像。两个频繁的缺陷是焊料中的空隙(以及相似的空气缺陷)以及陶瓷筏的倾斜或翘曲。

The IGBT shown in图2was imaged in this way using the 30 MHz transducer of a C-SAM® tool from Nordson Test & Inspection. When looking for defects and anomalies in IGBTs, the depth of interest often involves the solder layer between the heat sink and the ceramic raft on which the die are mounted. Two frequent defects are voids (along with similar air-filled defects) in the solder, and tilting or warping of the ceramic raft.

图中的图图1显示细节。此声学图像中使用的颜色图表示界面的深度。该图像的背景是焊料和陶瓷筏的底部表面之间的界面。

该界面的最深区域是淡蓝色的,在左下角的一个小区域中可见。最高的区域 - 最接近散热器的区域 - 右上角是鲜红色。随着界面从浅蓝色区域向上移动。它变成绿色,浅绿色,黄色,橙色,然后是红色。这些颜色之间的边界表明筏轮廓中有些不规则性。

超声脉冲到IGBT区域内的数千个X-Y位置中。回声反映在该区域内的所有内部接口,但只有来自将产生有用信息的深度的回声。脉冲遇到的第一个内部接口是散热器和焊料之间的接口。该界面中的所有回声都被忽略,但是即使收集了更深的一小部分材料界面。

所有黑色的黑色功能图2are air-filled voids just below, and likely in contact with, the heat sink. In the color map used here, black means “no echo from this x-y location.” The gate—the depth from within which echoes will be accepted for imaging—begins just below the heat sink. It does not include the heat sink to solder interface, because this interface would be the same color everywhere. The large and small voids near the top of the solder are black because their top surfaces lie just above the top of the gate. They reflected the incoming pulses before the depth at which echoes collecting began, so the echoes were ignored. Their black color means “no echo received.”

堆叠的晶圆成像

图3是五个直接键合晶片的实验堆栈的180 MHz图像,用左侧的颜色图成像。白色特征是最深的。黑色,尽管在地图上较低,但仅表示“未收到信号”。五个晶圆具有四个内部接口,但是图3was gated to include only the first two interfaces below the surface being scanned.

图4在侧视图中显示堆栈的结构。橙色矩形代表在堆叠之前在其中一个晶圆中钻出的圆形孔。

In图3,他首先在晶圆1和2之间成像的接口,橙色显示了这些功能的顶部。这些特征顶部的固体对空气界面基本上反映了脉冲的100%,即使空隙中的空气仅是微米厚的一小部分。非矩形橙色的特征图4是晶圆1和2之间相同接口处的空隙;像钻孔一样,它们充满了空气。

Looking back at图3, the numerous white features are voids between wafers 2 and 3. The additional colors seen around two of the large voids don’t represent extensions of a void into higher depths. Rather, they’re caused by local variations in the bond quality of this material.

No part of the pulse crosses the solid-to-air interface at the top of a void. If there’s another void, or part of a void, directly below this void, it will not be imaged at this x-y position.

扁平物品的表面分析

In addition to measuring the depth of internal features very precisely, the AMI tool can image the surface profile of items that are flat or supposed to be flat. The basic technique is the same: A pulse is launched toward the target at each x-y location, but only the reflection from the water-to-component surface interface is collected and used for imaging. The travel time of the received echo is measured at each of thousands of x-y locations.

一个颜色分配给每个深度范围;试验结果ting acoustic image is essentially a topographic map of the sample’s surface. The technique itself is known as acoustic surface flatness (ASF). If the surface is flat, all pixels will have the same color.

图5is the ASF image of a small unpopulated printed circuit board, The purpose of imaging was to determine whether differences in altitude might put dangerous stresses on components that will be mounted on the board. The color map is essentially the same as the map used in Figure 2. The lowest points are red, at the far left corner, and the highest are pink, near the middle of the front edge. The full on-board color range extends approximately from 0.120 to 0.920 mm.

ASF通常在裸板上使用,以防止应力引起的电力缺陷,以切断连接。它也经常用于大面积组件(例如BGA),在BGA中,表面不规则性通常与可能导致场地故障的内部结构异常相吻合。

The time required to launch a pulse and receive an echo from each of the x-y locations on this sample is probably less than the time needed to receive a pulse from the deepest interface in the silicon wafer stack described earlier.

In both cases, though, the time required is so minuscule that the transducer can scan at high speed across the target, or across a tray holding many targets, and collect echoes from tens of thousands of x-y locations per second. The AMI tool instantly arranges the variously colored pixels made from the echoes into the acoustic image, and the internal features, both intended and defective, are made visible.