What you'll learn:

- Line-scan vs. area-scan cameras.

- 高速机器视觉系统进行检查的关键成分。

- 如何将晶圆与相机同步。

光学半导体检查提出了复杂的挑战,包括目标的尺寸较小和晶圆空间中个体模具的接近性。同时,由于不满足要求所涉及的风险,晶圆检查结果的质量至关重要。由于这些原因,具有极高速度和分辨率功能的视力系统在半导体检查中可以发挥重要作用。

哄骗高速,机器视觉区域扫描摄像机直接流到后端计算机进行处理。半导体检查的性质需要强大的图像处理器,例如图形处理单元(GPU)和现场可编程的门阵列(FPGA),以及高端和功能强大的中央处理单元(CPU),具体取决于配置和所需的吞吐量。

是什么组成了系统?

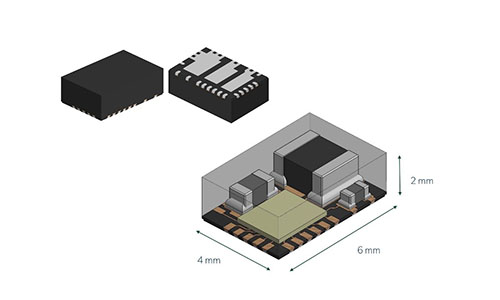

机器视觉系统由三个主要组成部分组成:高速摄像头,显微镜和空气X-y阶段,以保护晶圆的Z轴运动。相机与尼康LV-M显微镜集成(图。1)。

摄像头和显微镜都安装在Hybryx空气阶段,以隔离Z方向上的任何运动。空气阶段有助于避免可能偏向镜头焦距的野外深度(DOF)的任何不一致。

对于此测试,传感器的分辨率将减少到1920×1100像素,曝光时间为100 µs,速度为2500 fps,以满足检查要求。此外,空气阶段的X轴速度设置为每秒300毫米。该相机通过通用输入/输出(GPIO)电缆从系统控制器接收外部触发信号。

相机和晶圆同步

将单个模具单元同步在二维移动台中与摄像机的曝光时间同步是设置的关键部分。如果正确完成,则结果将是一致的图像分析,并具有定义的视野(FOV)。

The high-speed camera enables use of a GPIO cable to send external signals to the camera for trigger, sync, IRIG, and other functions. In this setup, the camera was synchronized with the speed of the table in relation to a single die unit, such that the trigger signal aligns with the exposure time of the frame. Alignment with the edge of the beginning of a single die within a wafer is thereby achieved. This precise synchronization of the trigger signal to the camera avoids a scenario in which the camera receives a trigger signal in the middle of a die.

The trigger-in signal should be sent at the beginning of the falling edge of the frame when the sensor begins exposure—with two consecutive falling edges defining a single frame. A time between a falling edge and a rising edge is an exposure time. Thus, in the synchronization process, the falling edge of an exposure time is where a trigger-in and sync signal is sent to the camera via the GPIO cable.

相机开始在模具的第一边缘捕获镜头。当相机看到模具的最后一个边缘或下一个模具开始之前,曝光就会停止。模具的第一个边缘与框架的下降边缘(曝光时间的开始)同步,并且模具的最后一个边缘与框架的上升边缘(曝光时间的末端)同步(图2)。The camera follows this task repeatedly, scanning the entire wafer.

As shown in图3, the key takeaway from this mechanism is that the entire die in a wafer can be precisely scanned in a very short period of time by synchronizing the external signal with the camera to capture an image with intended FOV, perspectives, and contrast.

A well-designed machine-vision system will improve product quality, decrease inspection time, and reduce takt, which is rate at the process can be completed. For semiconductor inspection, the faster the cycle time, the more quickly inspection can be completed. This ultimately reduces overall process time and production costs.

在我们的测试系统,实现高-speed camera increased the manufacturing and packaging process significantly by increasing wafer-per-hour inspection from 1 to 2 wafers to 10 to 15. To further analyze the data:

- v = 300 mm/s

- d = 1600 px×10 µm = 16毫米

- t = d/v = 16/300 = 53 ms/die

- per per wafer = 1000

- 总时间每晶片= 1000×53 ms/die = 53 sec〜 = 1分钟

假设由于软件图像处理,有100%的开销时间。每晶片的周期时间从1到2分钟。相机和软件处理的晶圆数量等于30晶片。这是ASML或类似系统每小时可以处理的15倍。

用高速区域扫描摄像机替换线扫相机可通过增加给定时间检查的晶圆范围的量来降低TAKT时间并增加产量。过去,线条设备因扫描较大的线条范围和后处理的缝合图像而被判处。但是,高速摄像头可以比线扫描摄像机扫描1,000倍,更不用说该图像可在没有图像缝合过程的情况下立即进行处理。

Conclusion

Machine-vision systems provide superior speed when implemented in semiconductor inspection, increasing quality of product and reducing takt and cost significantly. Previously, a line-scan camera was preferred to achieve relatively higher speeds by scanning larger surface areas and stitching lines to form a single frame. High-speed inspection of a larger surface area of a wafer can be achieved with a high-resolution area-scan camera, which scans significantly faster than a line-scan camera.