What you’ll learn:

- 为什么现代电子产品如此容易受到热机械疲劳的影响。

- How multiphysics software tools can aid the design process, resulting in better product longevity.

车上的安全气囊……视频门铃上的相机……您现在正在阅读的手机或其他电子设备。如果没有关键的电气组件,可以使现代生活成为可能的日常产品无法运行多年。

And yet, these electrical components experience complex thermal and mechanical loads during the daily course of their operation, or, in the case of the airbag, during long-term passive cycles of environmental heating and cooling while they wait unused within a car’s interior. As producers and consumers require ever more from electronic devices, those devices are becoming more powerful, further increasing the thermal loads being subjected to vital components.

传热和热负荷

电路板加热时会发生什么?

Heat can come from various sources and affect circuits in different ways, especially as circuit boards are assembled with increasing density in efforts to make smaller, lighter circuit designs. Heat can be damaging. Printed-circuit-board materials are formulated to withstand a certain amount of heat, but when the temperatures rise to high enough temperatures, circuit performance can suffer, especially at higher frequencies.

One day-to-day example of this is the thermal throttling of our cellphones. As your phone heats up, the phone reduces performance to protect the device, which you notice from the slower response of your phone.

This same type of behavior can occur in large data centers or industrial automation controllers. Typically, these devices have built-in thermal protection. If the processor gets too hot, the built-in protection shuts down the processor.

Thermomechanical Fatigue

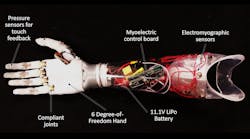

即使设备未关闭,热负载,尤其是热负载中的差异也可能引起设计问题。热量导致大多数材料扩展,随后的冷却导致收缩。此外,各种组件材料将以不同的速率扩展和收缩,并且由于使用变化而导致的热负载通常会随着时间而变化。

例如,电子设备通常进入“睡眠”模式以节省能量。发生这种情况时,热负载和工作温度会降低。这种环状负荷会产生少量的疲劳损伤,最终会在关键组件中产生裂纹。这些裂缝可能会导致组件故障。

多物理模拟工具的作用

Engineers are tasked with developing new designs that can withstand increased loadings. But they also must incorporate the expectation of numerous repeated cycles of increased and decreased thermal loading into their designs, with an eye for longevity. One solution to this challenge is to use multiphysics software tools to calculate the lifetime of electronics components before they’re put into production or lengthy testing processes.

These tools can be beneficial in numerous scenarios. They’re a natural fit when considering entirely new designs being built from the ground up, subjected to holistic testing and prototyping during the R&D phase.

Often, though, manufacturers seek to merely tweak specific components within an existing design. As a result, they either don’t properly anticipate the effects that small changes can have on thermomechanical balance and product longevity, or need a way to predict these effects without going through a lengthy and expensive prototyping process. Multiphysics simulation tools can be invaluable assets in both situations.

早期合作伙伴

传统上,电子组件的热设计在设计过程中一直处于相对较晚的阶段,当时许多电子设备和机械设计都接近完成。由于物理原型过程中发现的问题,这导致了许多晚期设计的返工,并且通常会进一步迭代。

Consequently, this can mean design costs skyrocket, products are frequently late to market, and there’s not enough time to explore better design approaches and optimization strategies in the upfront design phase where simulation has the most impact.

通过使用解释传导,对流和辐射的多物理模拟,工程师可以评估不同的关键指标,包括传热速率和连接温度,并可视化关键区域中热量的分布。工程师可以轻松测试其设计,而不会浪费宝贵的时间和资源。

仿真是评估和优化广泛原型几何和工作条件下的热转移过程的快速且具有成本效益的方法。

确保设计寿命

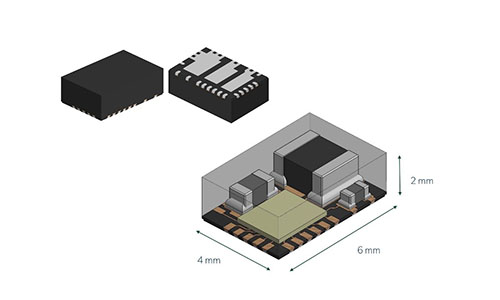

多物理软件工具还可以执行热机械应力和疲劳分析,从而计算电子组件的寿命。这些模拟包括由组件产生的热量,围绕组件周围的空气流以及从组件产生的辐射传热。

计算热环境后,可以确定温度变化对组件应力的影响。然后,应力和应变构成了使用疲劳损伤模型来计算组件寿命的基础。这种方法使工程师能够使用期望的一生设计电子设备。

One example of this type of analysis is the fatigue cracking of solder in ball grid arrays (BGAs). This failure mode is often driven by a combination of thermal gradients and mechanical constraints.阿尔塔西姆已经进行了这些分析,以帮助机械工程师更好地了解产生故障模式和缓解方法的因素。这些分析通常在初始设计阶段没有进行,但是当原型过程中BGA失败时,它们非常有用。

过程效率

多物理软件仿真为电子组件设计行业提供了极大的机会。独特的精通模拟工程师可以无缝地插入公司的现有工程功能,从而提供其设计概念的快速,高质量的虚拟原型,并确定潜在的问题和解决方案。最终的效率和成本节省使模拟在设计过程中的多个点上是明智的选择。